75 Restoration

Posted: Sun Apr 19, 2015 12:22 pm

Where to begin?!

I bought the 1975 Fiat 124 Spider 1800 from a guy on more-or-less a whim in August of 2014. After finding the car and doing a bit of research I found the spider even more desirable. When I went to look at it, it seemed that the PO rattle canned the body, certainly rattled the engine without masking anything off, leading to over spray on just about everything. There was oil leaking badly from the head. The carpet was torn an not secured anywhere. There were wires hanging down everywhere, rust in wheel wells, firing on 3 cylinders, it was in rough condition.

I talked him down a bit on the $(still more then I should had paid), bought it, bought new plugs and wires, and took off down the road. I got it to my folks' house so the old man and my ma could take a spin, they are great people who have never had much for luxuries. That was fun for us!

The main goal of this car is to fix it up and have it be a daily driver in the summers but also to be able to drive off with my soon to be wife from our wedding that is coming up in two months. This gave me the winter to get the car in good order.

I realized quickly that I had more work to do then I first thought. So I stepped up the pace a bit.

I patched up the floors and kick panel. Fab'd new D&P seat mounts

Took 3 layers of different paint and primer off and primed, painted, and cleared

Replaced old heat and sound resin with new

mostly all new rubber seals and gaskets for the whole vehicle

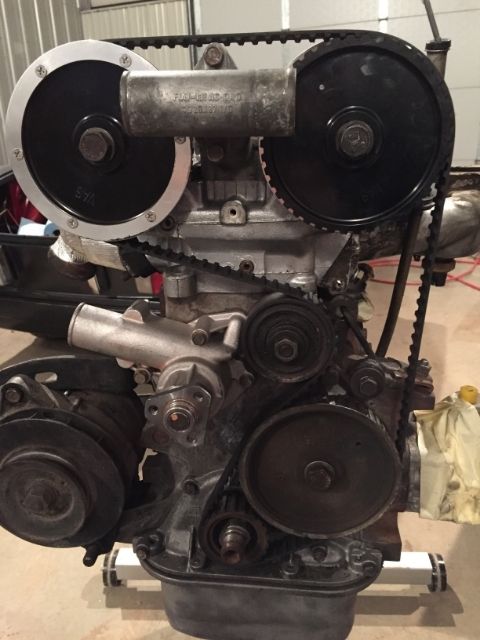

Rebuilt the motor ( had Hedahls in Aberdeen S.D do it, running out of time!!)

- Cleaned, inspected, bored, and used an Engine rebuild kit from Vic's

I have replaced the wiring with a painless performance kit.. most of the components still need to be connected

I have to connect the new clutch and trans then instal.

I have a new alt, starter, coil, wires, plugs, cam pulleys, belts, brake lines, radiator, hoses,

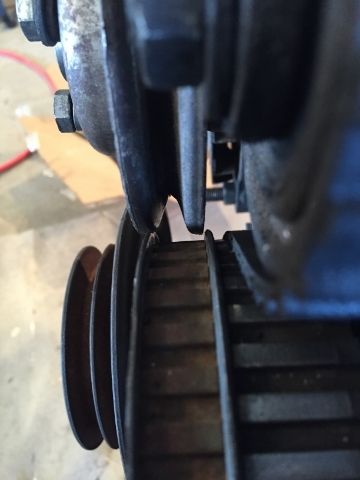

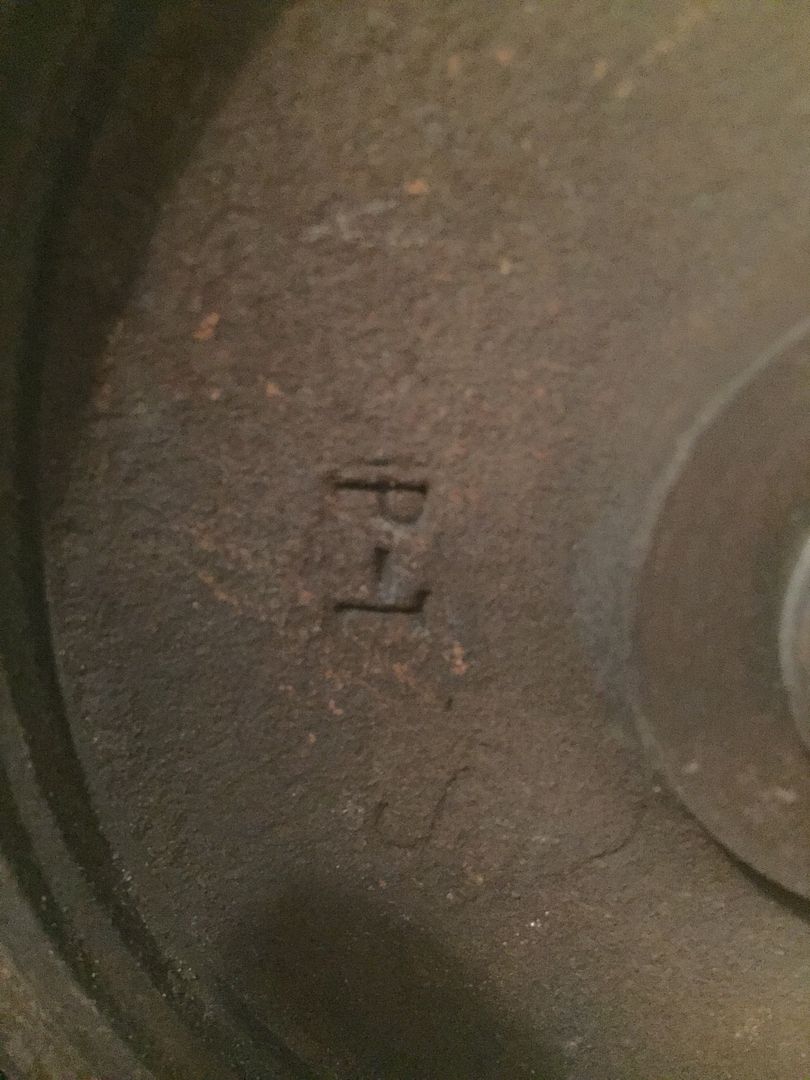

I am having some difficulty with putting the pulleys back on. The crank is not seating all the way because of the aux pulley. I have not yet figured it out but once I do I'll be able to get the engine timed(hopefully, certainly with help from FS!) and then installed.

I'lll post pics Soon with the various stages of progression

ANY ADVICE IS SO DEARLY WELCOMED

I bought the 1975 Fiat 124 Spider 1800 from a guy on more-or-less a whim in August of 2014. After finding the car and doing a bit of research I found the spider even more desirable. When I went to look at it, it seemed that the PO rattle canned the body, certainly rattled the engine without masking anything off, leading to over spray on just about everything. There was oil leaking badly from the head. The carpet was torn an not secured anywhere. There were wires hanging down everywhere, rust in wheel wells, firing on 3 cylinders, it was in rough condition.

I talked him down a bit on the $(still more then I should had paid), bought it, bought new plugs and wires, and took off down the road. I got it to my folks' house so the old man and my ma could take a spin, they are great people who have never had much for luxuries. That was fun for us!

The main goal of this car is to fix it up and have it be a daily driver in the summers but also to be able to drive off with my soon to be wife from our wedding that is coming up in two months. This gave me the winter to get the car in good order.

I realized quickly that I had more work to do then I first thought. So I stepped up the pace a bit.

I patched up the floors and kick panel. Fab'd new D&P seat mounts

Took 3 layers of different paint and primer off and primed, painted, and cleared

Replaced old heat and sound resin with new

mostly all new rubber seals and gaskets for the whole vehicle

Rebuilt the motor ( had Hedahls in Aberdeen S.D do it, running out of time!!)

- Cleaned, inspected, bored, and used an Engine rebuild kit from Vic's

I have replaced the wiring with a painless performance kit.. most of the components still need to be connected

I have to connect the new clutch and trans then instal.

I have a new alt, starter, coil, wires, plugs, cam pulleys, belts, brake lines, radiator, hoses,

I am having some difficulty with putting the pulleys back on. The crank is not seating all the way because of the aux pulley. I have not yet figured it out but once I do I'll be able to get the engine timed(hopefully, certainly with help from FS!) and then installed.

I'lll post pics Soon with the various stages of progression

ANY ADVICE IS SO DEARLY WELCOMED