Page 3 of 5

Re: What to do first!

Posted: Wed Apr 03, 2013 9:47 pm

by dmwhiteoak

Glyn, I'm glad I could help. Now just get it installed and on the road. Keep us posted on the progress.

Re: What to do first!

Posted: Wed Apr 03, 2013 10:31 pm

by Glyn

I'm taking advantage of motor being out and replacing all the bushing on the suspension and steering. A lot of work and slow going. Maybe just need a bigger hammer! Thanks again on the motor Dennis. I will send up dates.

Re: What to do first!

Posted: Thu Apr 04, 2013 3:58 am

by giuliot60

You do know that most of the vendors sell new A-Arms with bushings and ball joint installed, right? It may seem like more money, but time spent on replacing rubber is way shorter.

Make sure to read up on how and when to torque the A-Arm bolts. The car should be fully loaded, and with the engine out you may want to wait to do the final torquing until you get it back in. I haven't replaced my front suspension parts yet, so I don't speak from experience, only from what I've read since I'll be doing it soon.

Re: What to do first!

Posted: Thu Apr 04, 2013 7:52 am

by RRoller123

Be aware that there has been a confirmed problem with some A-Arm bolts being slightly too long, so you hit torque when the threads bottom out but before the system is truly tight. A couple of SS washers fixes the problem, (or a replacement bolt). There is a long thread elsewhere on the forum about this. I discovered the problem and Ramzi and Csaba researched and verified it. Another vendor denied its existence. The symptom I saw was that the upper bolt on my car would rotate fairly easily in the system, even after I had torqued it to spec. Easy to check.

Pete

Re: What to do first!

Posted: Thu Apr 04, 2013 11:27 pm

by Glyn

Thanks for the suggestions. I did not know about needing to be at running weight before torque, thanks. I will check bolt length when re-assembling but it was snug when I took it off. Yes, I saw the threads about all the trouble people have had doing this. I already had ordered the bushing and have pulled off arms on both sides. Plan to take them to local auto shop to see how much they will charge to remove and press in new ones. If had to do it over might have just ordered complete unit. Rented ball joint vise but did not work for this. Looks like you need a puller of some sort. I tried to press one out with vise and did not seem to work very well.

Re: What to do first!

Posted: Thu Apr 04, 2013 11:40 pm

by Glyn

Re: What to do first!

Posted: Thu Apr 04, 2013 11:55 pm

by giuliot60

You go boy!

How hard was it to remove the spindle from the ball joints? I heard some horror stories.

Re: What to do first!

Posted: Fri Apr 05, 2013 1:04 am

by Glyn

Not that hard, may have been lucky. My dad and friend who work in salvage yard both said good rap on outside. I back off the nut but not off so when it gave it stayed. Each one took 2-3 good hits with hammer and pop. I also read the stories of all the trouble people had getting them off. Went to friend and ask if he had a fork I could use and he said yes but never used it saying it tore up the rubber and never needed it. He and his brother took off hundreds when a new scrap car would come in to salvage yard and hammer was much faster.

Re: What to do first!

Posted: Fri Apr 05, 2013 1:18 am

by giuliot60

Like!

Hopefully I'll be as lucky

Re: What to do first!

Posted: Fri Apr 05, 2013 11:57 pm

by Glyn

Toughest repair item to date! It was a war, lost a few battles on the way but prevailed. All most embarrassed to tell how I changed the bushing on the A arms it was not pretty. Don’t know how anyone can pull the old bushing out. The top arms were easier, heated up rubber and push out metal ring in middle and then pulled out rubber with screw driver. Yes, there was a small fire when rubber burns but not bad. I then took out jig saw with metal blade and carefully cut the outside part of bushing. Once cut used chisel to crush in ring inward then they just come out. The lower arms were a little harder getting rubber out same basic process with the exception of burning rubber off using chisel to help pull rubber off the two sides. Then used drill and tried to drill out as much rubber as I could. Then used screw driver to get all rubber out. With the bar still in there used jig saw again even though it was a little tighter it still worked.

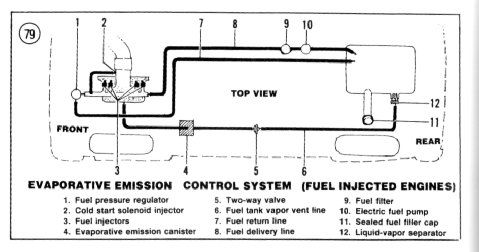

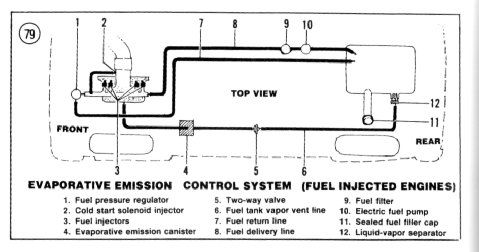

Does anyone know what this is far? It is located right in front of the gas tank under the car. Whatever it is mine is clogged solid. Do I need it?

Re: What to do first!

Posted: Sat Apr 06, 2013 2:40 am

by 4uall

I believe it is a Check Valve Fuel 1-Way

http://en.wikipedia.org/wiki/Check_valve

http://en.wikipedia.org/wiki/Check_valve

Re: What to do first!

Posted: Sat Apr 06, 2013 12:56 pm

by Glyn

Looks like mine was checking everything, filled up solid. Will have to replace. Thanks.

Re: What to do first!

Posted: Sat Apr 06, 2013 4:06 pm

by Glyn

Which ways is the the flow going through the check valve? Flow toward tank or engine?

Re: What to do first!

Posted: Sat Apr 06, 2013 4:45 pm

by giuliot60

According to the service manual, the 77-80 and FI systems don't have the check valve, but a 2-way valve on the fuel vapor line going back to the tank. 75s-early 77s had them between the tank and pump, so it would probably be traveling to the engine. But since your car is a 78, it should have the first scenario.

The turbo had a plastic check valve between the manifold and charcoal canister. And since my car was a turbo, I have one. Now I need to find out if I need it.

Re: What to do first!

Posted: Sat Apr 06, 2013 7:43 pm

by RRoller123

This may help, not sure: