Page 2 of 19

Re: 1980 spider Restoration phase 2

Posted: Tue Jul 19, 2016 12:51 am

by RRoller123

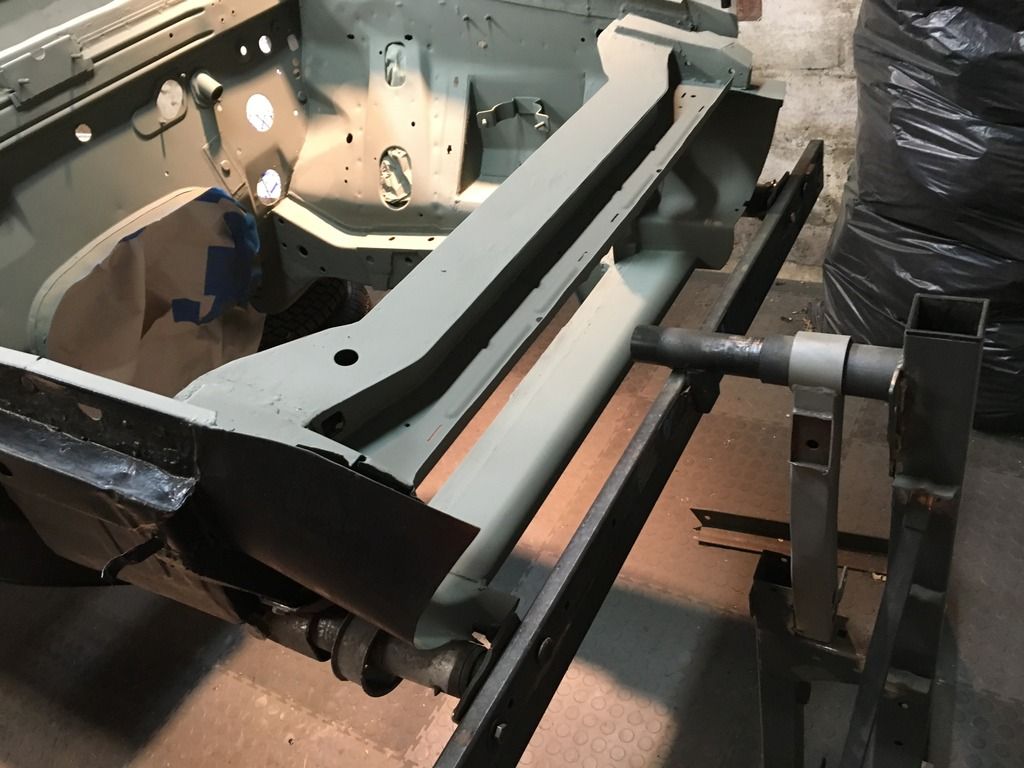

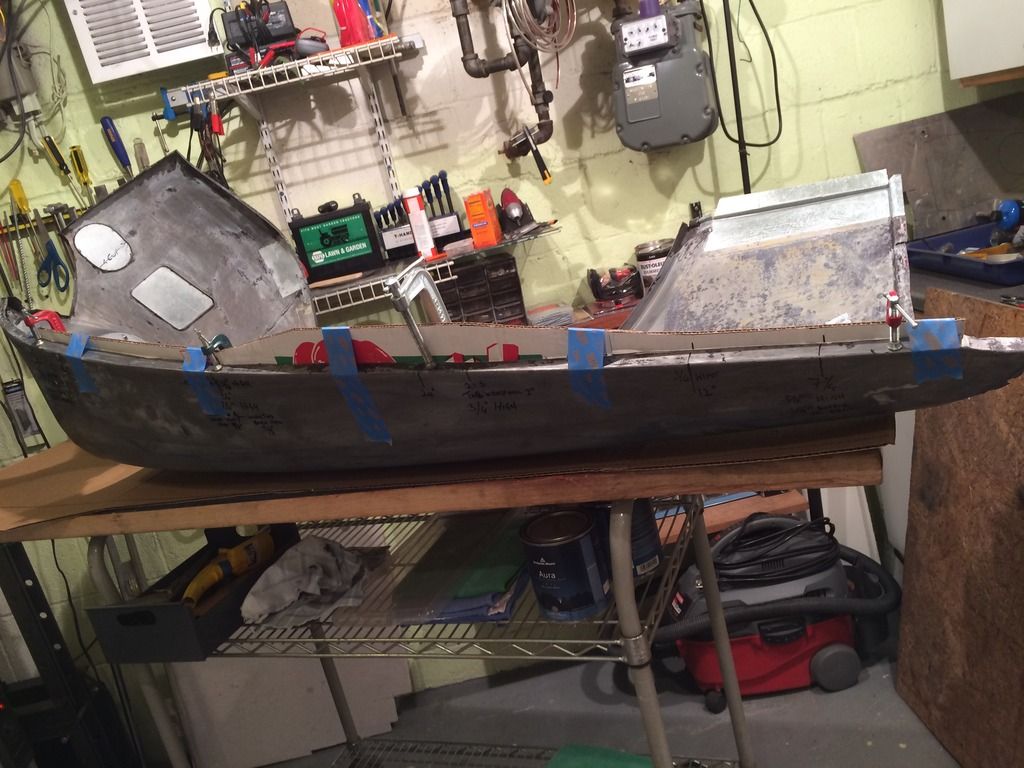

I am always amazed at the work that you guys do with metal, really nice to see a car come back, that to me, looks too far gone. But then, a while later, we look and there it is in full beautiful glory! Good for you, excellent stuff.

Re: 1980 spider Restoration phase 2

Posted: Tue Jul 19, 2016 3:44 pm

by bluespider262

Great work you are a true craftsman.

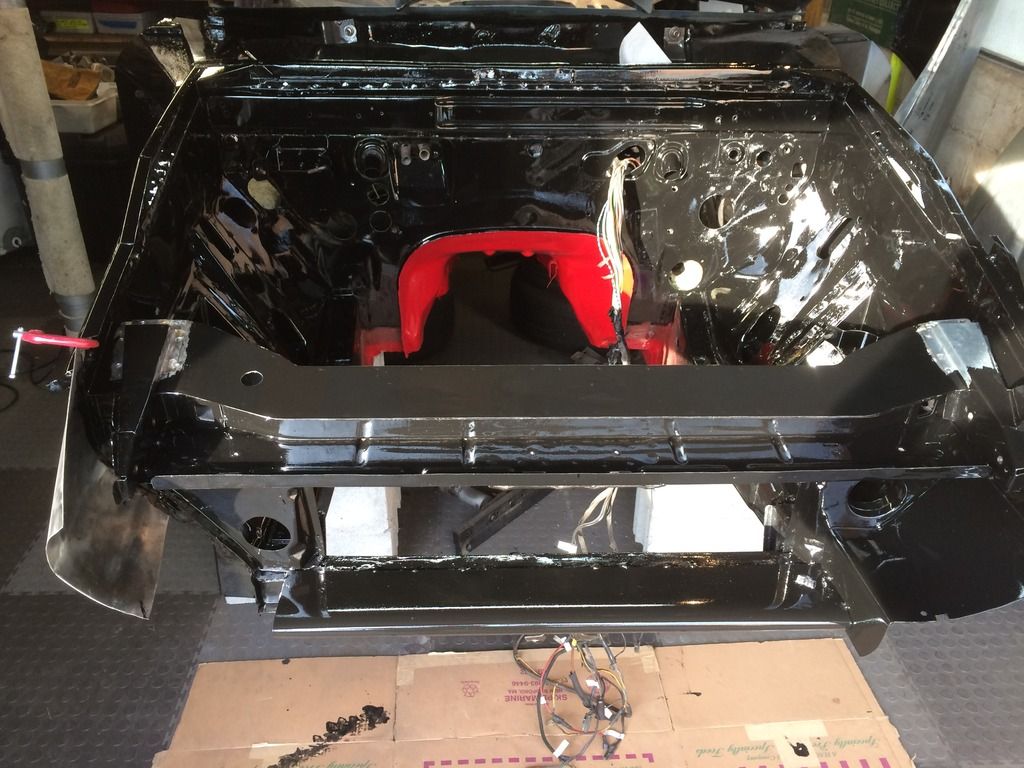

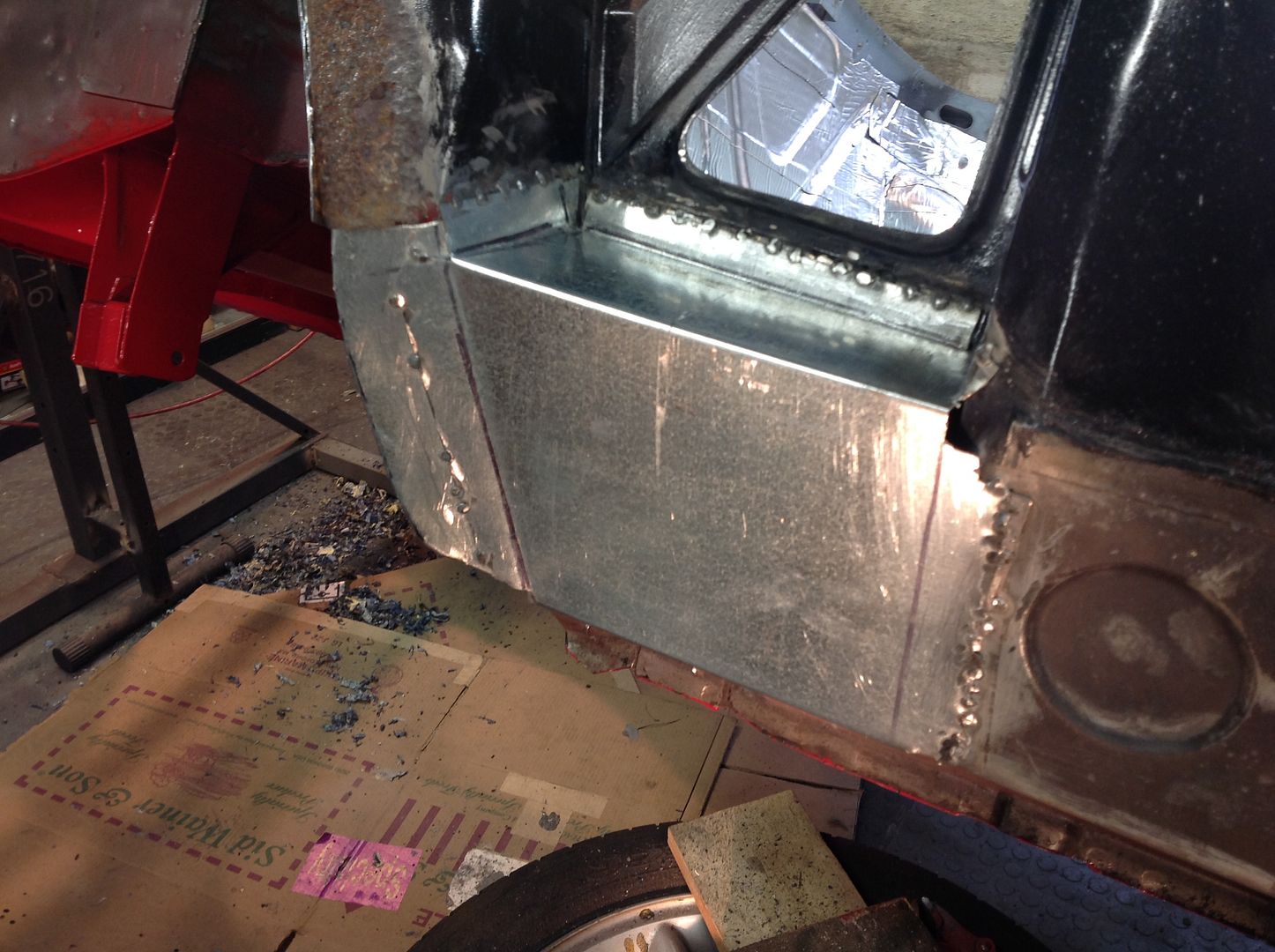

Why red on the underside - is that going to be the color of the car?

Re: 1980 spider Restoration phase 2

Posted: Thu Jul 21, 2016 11:47 pm

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Fri Jul 22, 2016 12:01 pm

by bluespider262

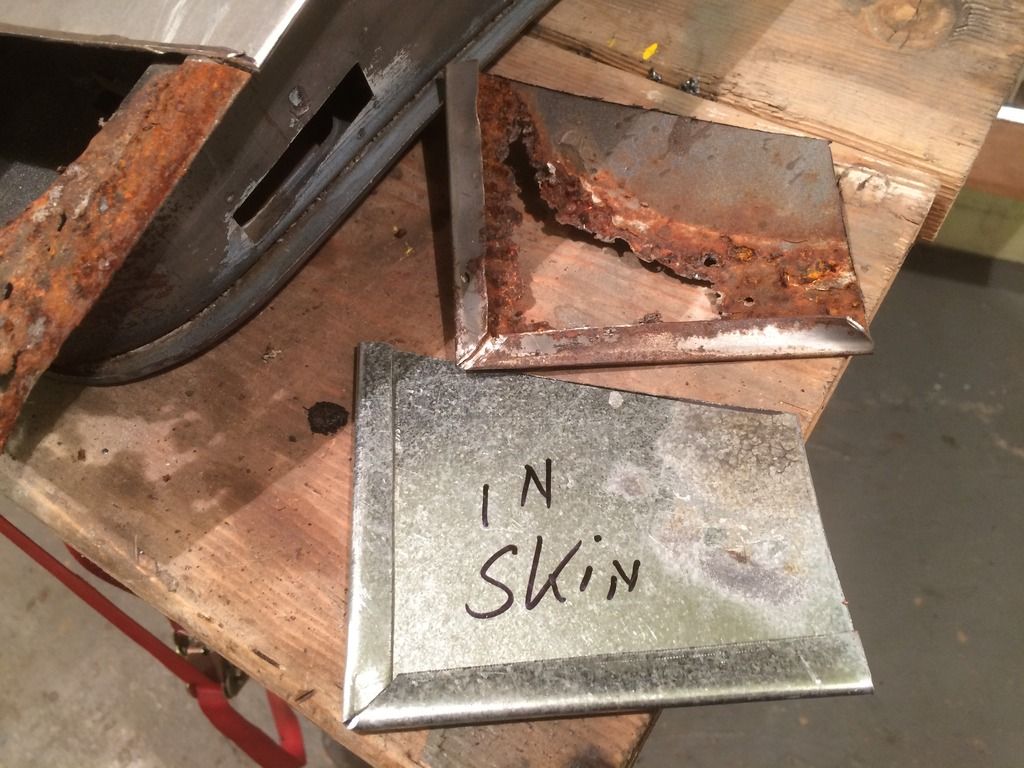

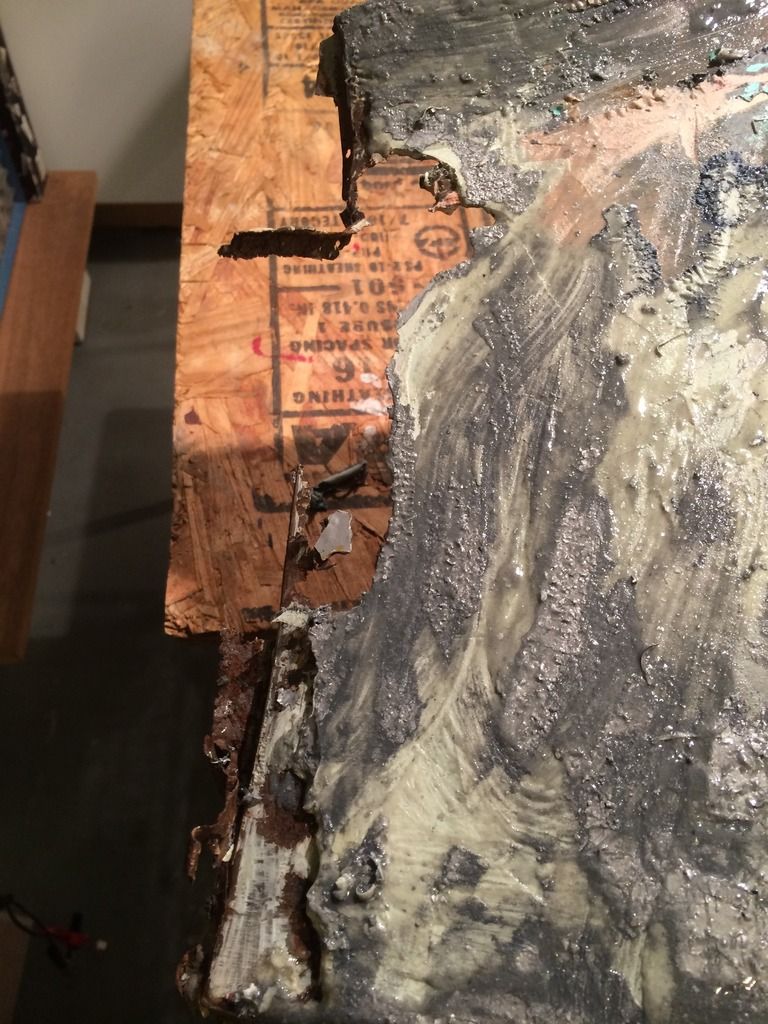

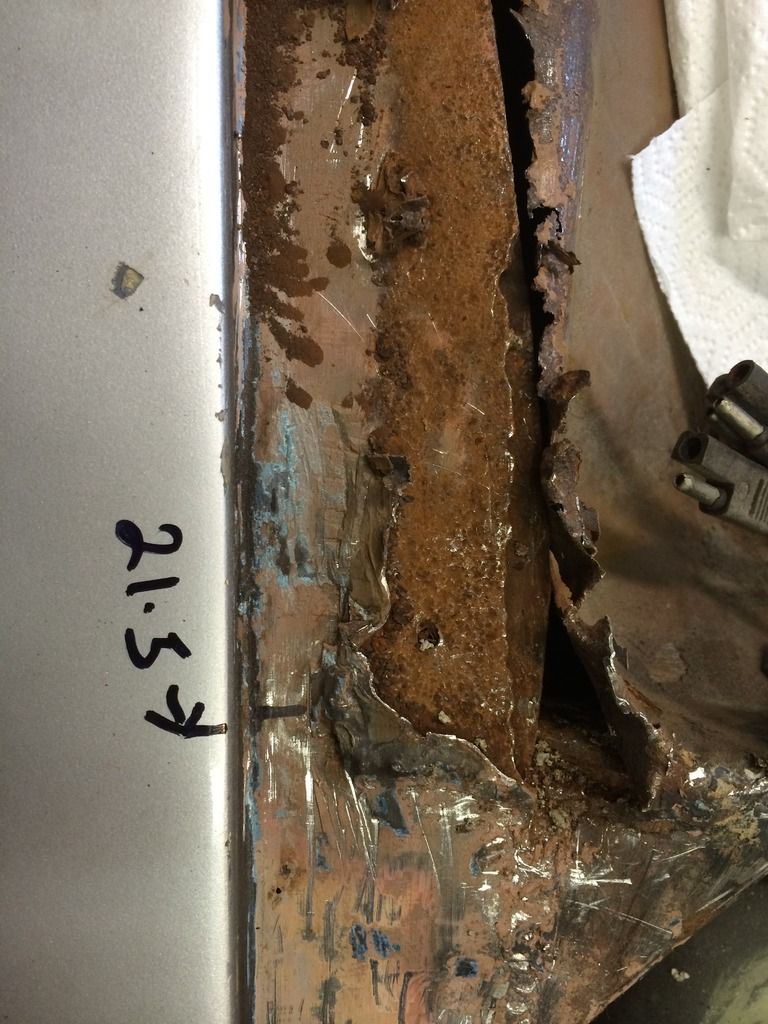

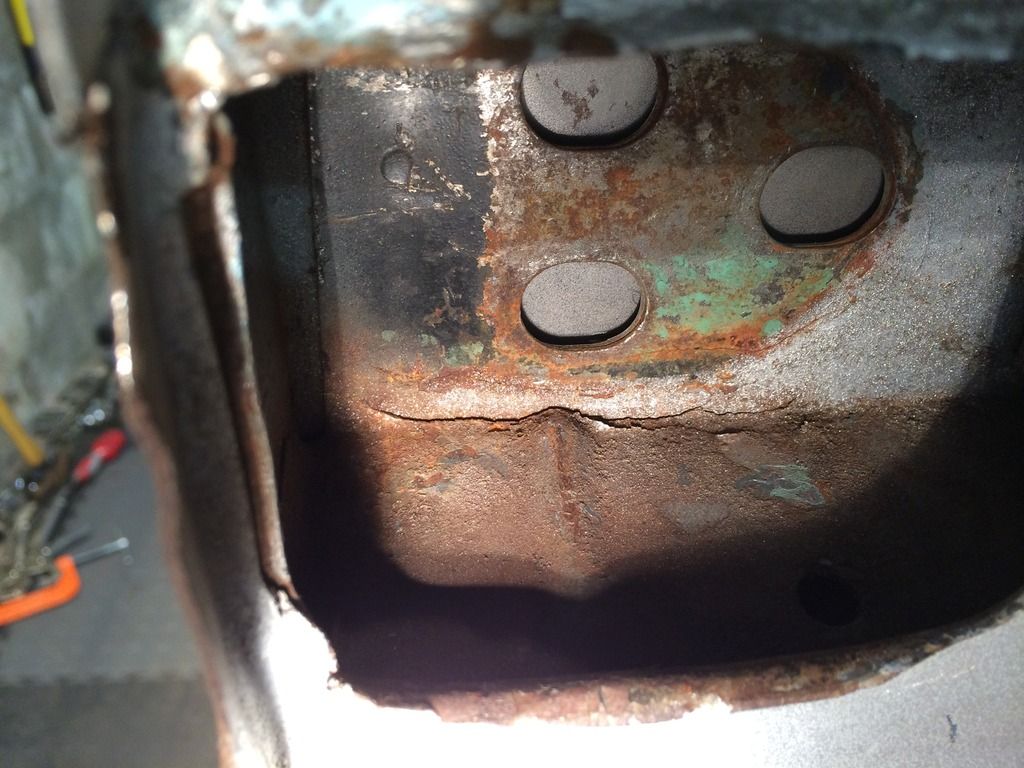

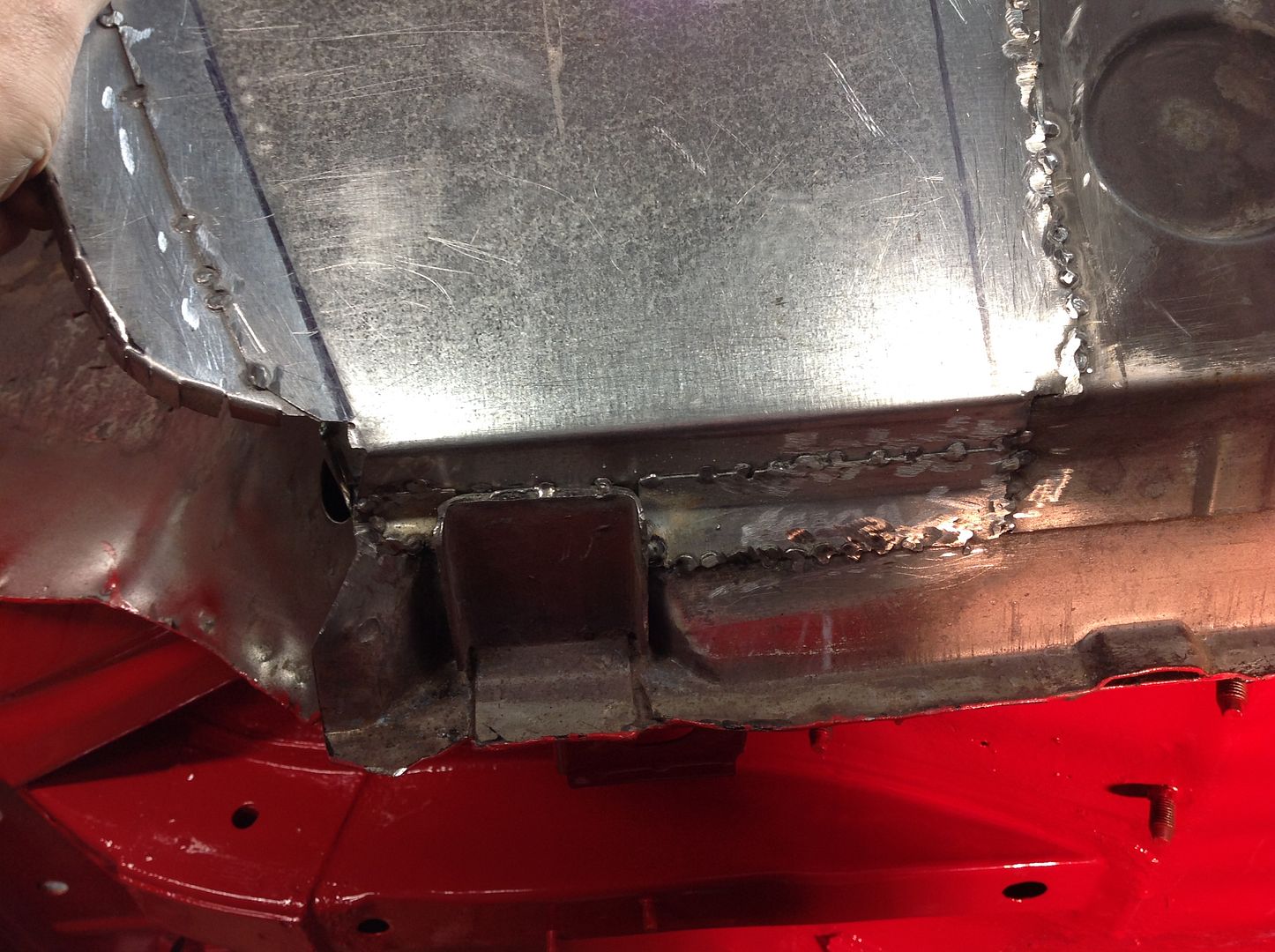

Amazing how much rust was hiding behind those tiny bubbles.

You are making me worried about my car now!

Re: 1980 spider Restoration phase 2

Posted: Sun Jul 24, 2016 8:31 am

by DRUMMOND

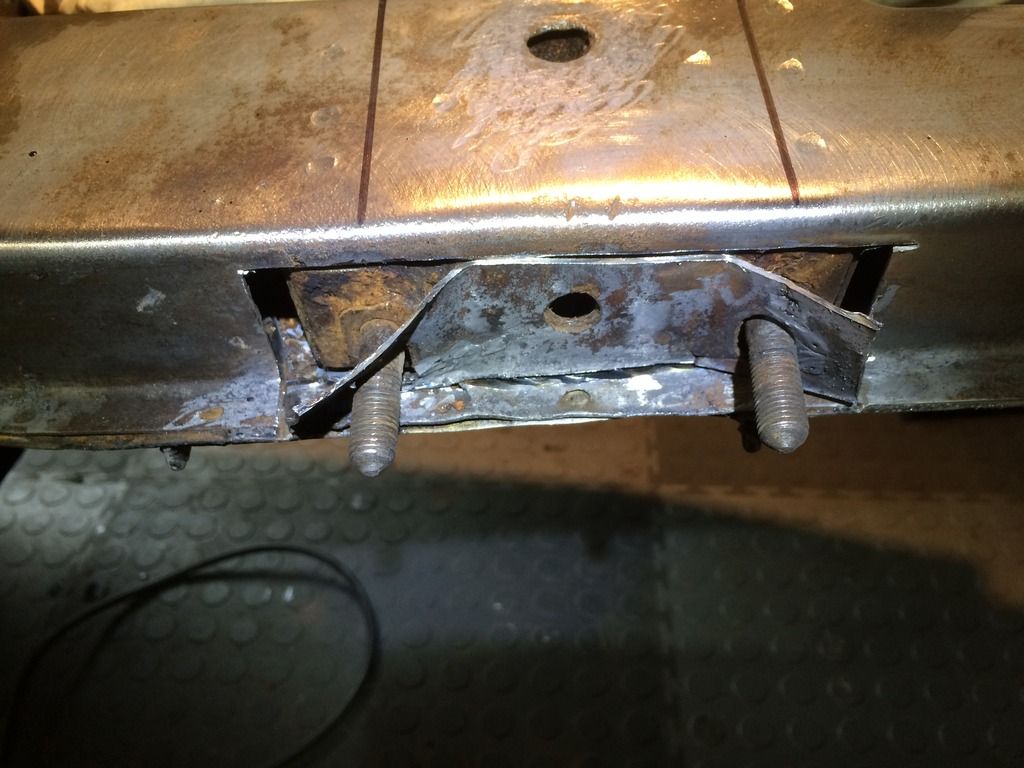

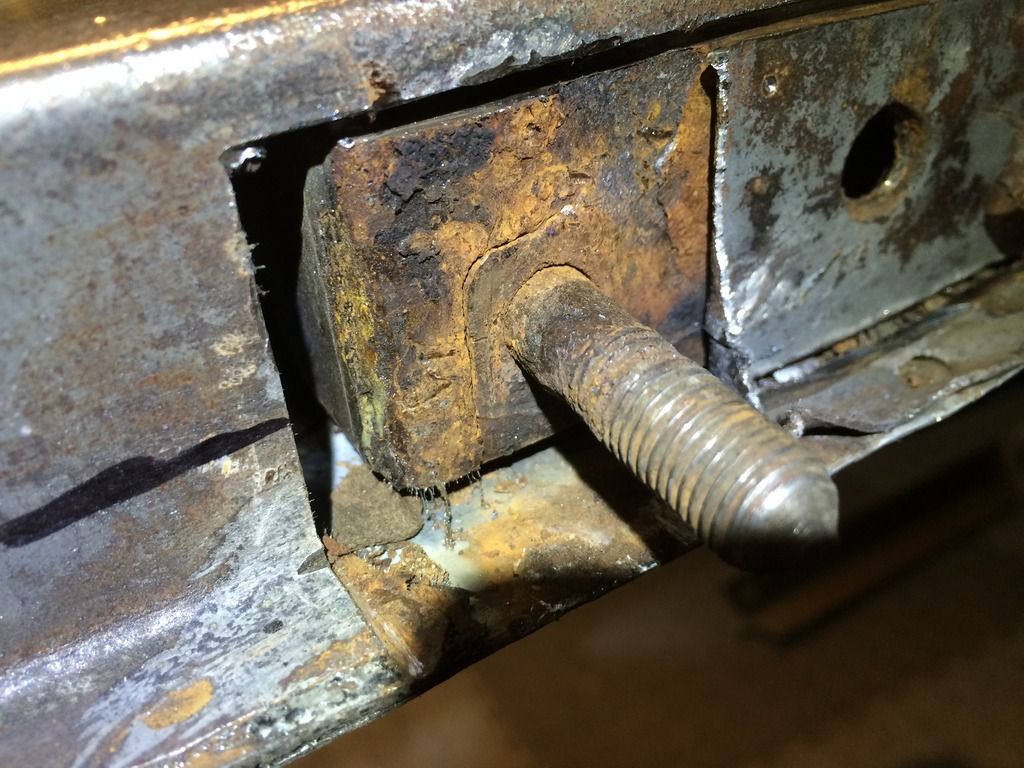

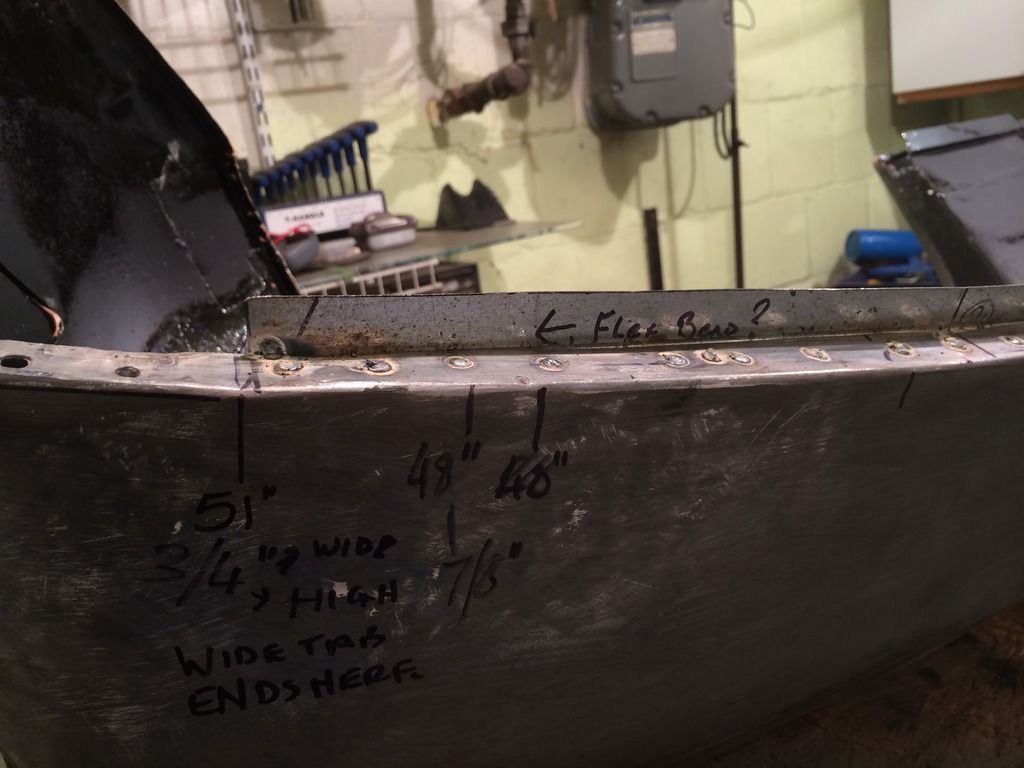

As I progress through this renovation i am thinking a little seam sealer & some decent paint would have prevented 90% of the rust problem.

Why they choose not to use it in some major structural areas and use it in non structural areas is beyond me!

One of the areas that shocked me, was the installation of the air conditioning cooling radiator, they cut the front of the car with a blow torch and never even protected the cut metal just left it a molten mass?? rusted out the lower cross-brace, A five minute prevention would have kept it good.

Re: 1980 spider Restoration phase 2

Posted: Tue Jul 26, 2016 5:31 pm

by TXWarthog

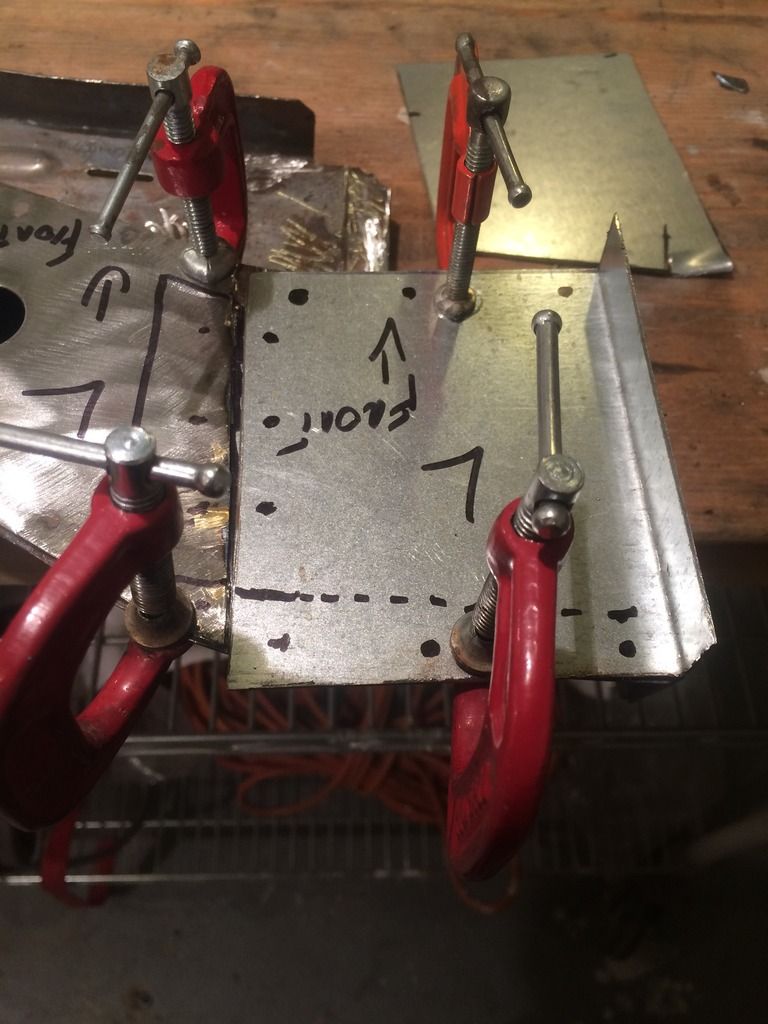

When you secured the gussets in to help flush in the door patch, did you use a spot welder? I was thinking either it was a spot welder, or you've got some great welding skills!

If you have a spot welder, what type do you have (120v, 240v)? I'm considering getting a 120v Harbor Fright (yes, it's pun spelling) spot welder.

Re: 1980 spider Restoration phase 2

Posted: Tue Jul 26, 2016 7:24 pm

by DRUMMOND

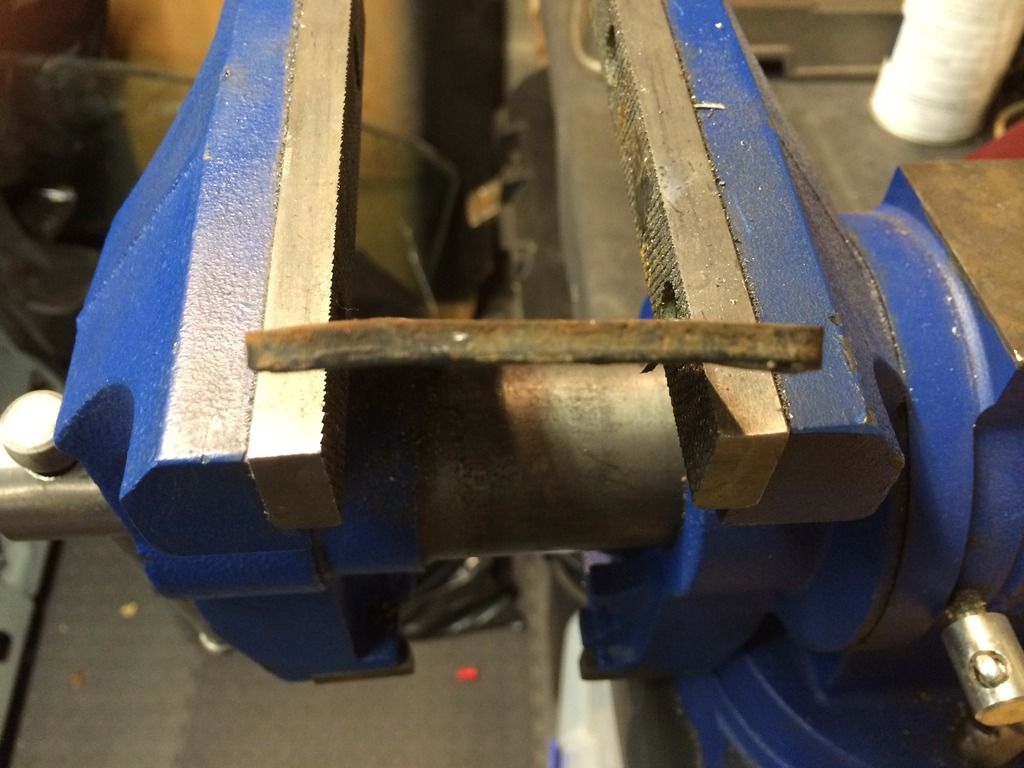

I have no spot welder (I wish) This is my pet welder, we have known each other intimately for 2 years.

This is the setting I use for Modern steel, for the cheap Russian steel that has not rusted yet! I use level A Any higher and it just blows through it

Good grounding is essential for the crackle (a good weld spot)

Re: 1980 spider Restoration phase 2

Posted: Tue Jul 26, 2016 7:25 pm

by DRUMMOND

forgot to post the picture

Re: 1980 spider Restoration phase 2

Posted: Tue Jul 26, 2016 9:31 pm

by TXWarthog

Awesome. That takes skill to do those spots with a welder! I see a gas shielded wire fed welder in the near future (to sit next to the cheap Harbor Freight flux core wire fed welder I have now).

Re: 1980 spider Restoration phase 2

Posted: Tue Jul 26, 2016 11:49 pm

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Wed Jul 27, 2016 12:08 am

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Mon Aug 22, 2016 11:54 pm

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Tue Sep 13, 2016 10:26 pm

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Wed Sep 14, 2016 10:02 am

by RRoller123

Man that is some talented work!! So well documented. Thanks for sharing.

Re: 1980 spider Restoration phase 2

Posted: Wed Sep 14, 2016 10:58 pm

by DRUMMOND