Page 8 of 19

Re: 1980 spider Restoration phase 2

Posted: Mon Mar 13, 2017 10:35 pm

by DRUMMOND

Thanks Neksonj

Mark

It is a marker/indicator light (bmw)

Re: 1980 spider Restoration phase 2

Posted: Mon Mar 13, 2017 11:18 pm

by Gatorman

Fantastic job Drummond! I can't imagine how many hours you have in this project. Love the new color!

Re: 1980 spider Restoration phase 2

Posted: Sun Mar 19, 2017 11:20 pm

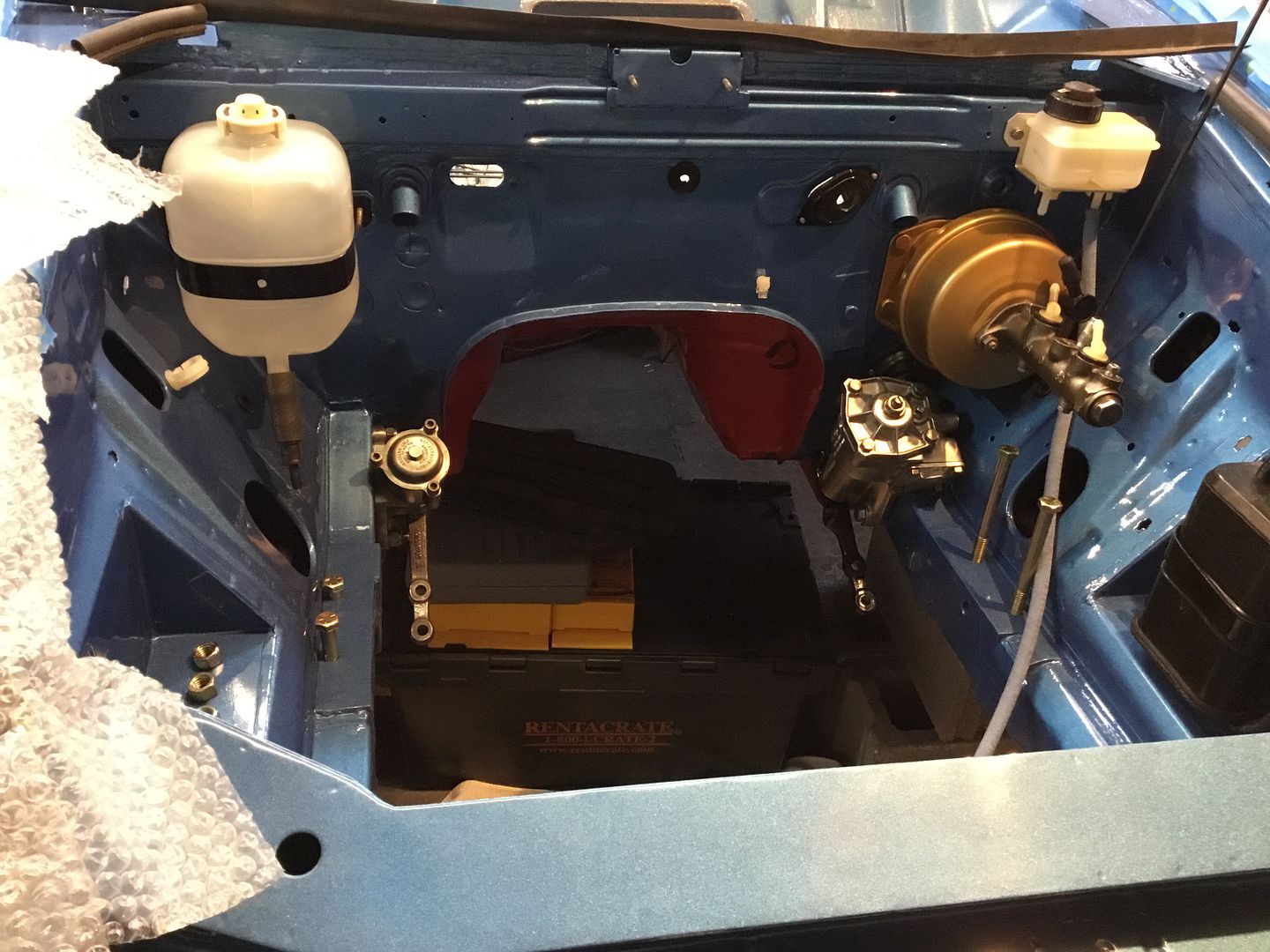

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Mon Mar 20, 2017 2:58 am

by Mick124

Nice work Drummond. Love the color.

Re: 1980 spider Restoration phase 2

Posted: Tue Mar 28, 2017 12:03 am

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Fri Mar 31, 2017 7:49 pm

by Kiwispider

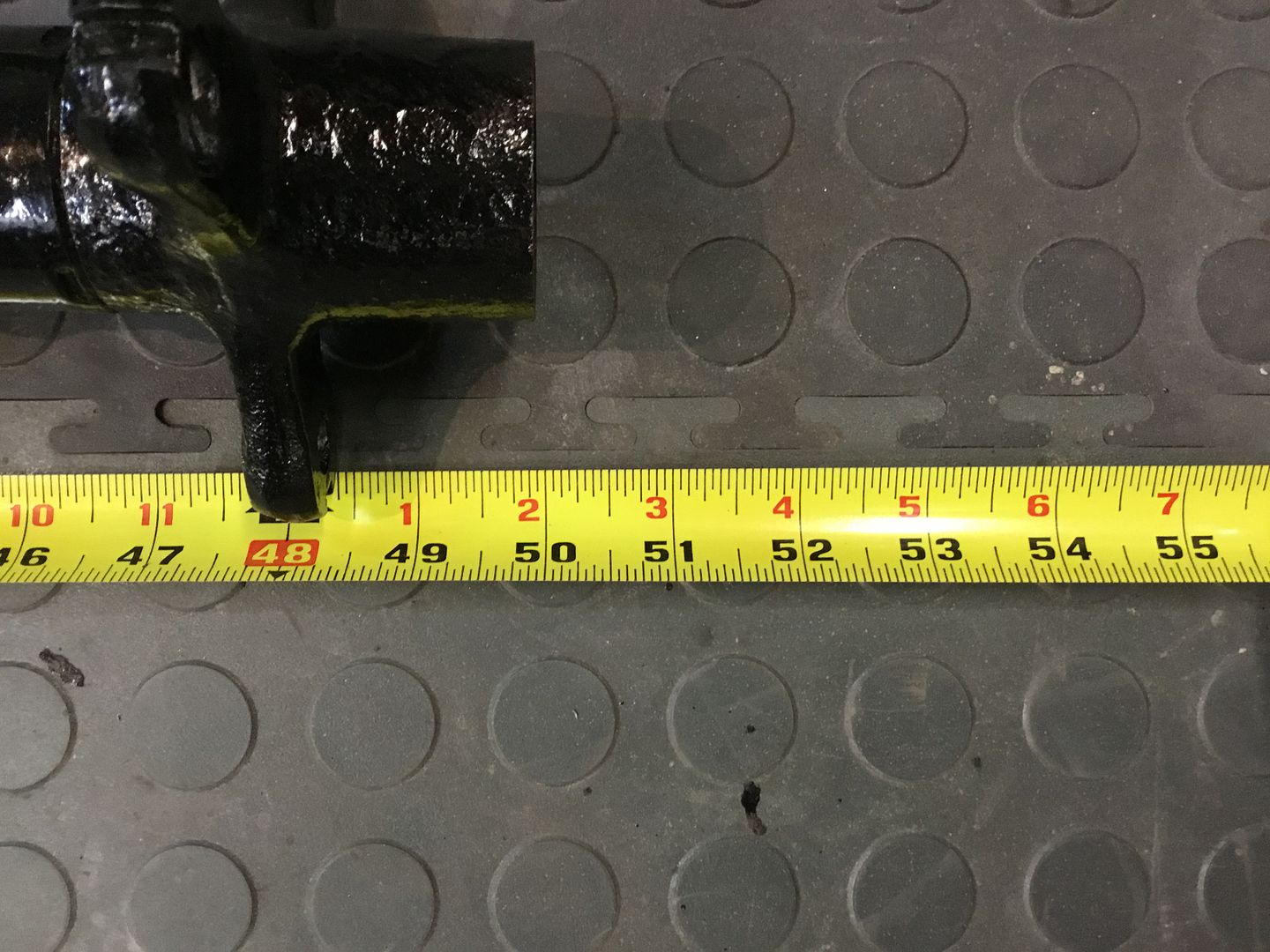

Hi Drummond, assuming you still have your drive shaft out? I'm swapping out my auto gearbox for a 5 speed so need to get my front drive shaft lengthened - any chance you could measure yours so I know how long to make it?

Also when you refurbed your sliding yoke did you pull it apart? Could it/should it be done? I have second hand one that came with the 5 speed box, don't know if it is different to the one on the automatic.

Thanks

Re: 1980 spider Restoration phase 2

Posted: Sat Apr 01, 2017 11:45 pm

by DRUMMOND

Hi Trevor

Here are the driveshaft measurements

Driveshaft was totally disassembled re-greased Spiders, yoke & new center support. If unknown condition, check play/condition at yoke/spline side

Re: 1980 spider Restoration phase 2

Posted: Sun Apr 02, 2017 12:24 am

by DRUMMOND

Re: 1980 spider Restoration phase 2

Posted: Sun Apr 02, 2017 8:11 am

by aj81spider

I continue to be amazed by your work. I love this thread and the fact that you are restoring and not replacing most things - and that they keep turning out fantastic.

I saw you respond on another thread to someone that something "was no big deal and just required a little care." I didn't reply, but wanted to warn him that's like Michelangelo telling someone that painting church ceilings was no big deal!

Re: 1980 spider Restoration phase 2

Posted: Sun Apr 02, 2017 8:06 pm

by azruss

I see you are using a thread tap to chase the threads. I would recommend using a roll tap as the method you are using now is removing material and weakening the threads. A roll tap will reform the metal without removing any, making for a stronger thread.

Re: 1980 spider Restoration phase 2

Posted: Sun Apr 02, 2017 11:48 pm

by DRUMMOND

Hi aj81 spider. Thank you for your kind comments!

Hi Azruss. No metal is being removed, Just paint and surface rust. I was of the opinion that a roll tap was for forming not thread chasing?

Re: 1980 spider Restoration phase 2

Posted: Mon Apr 03, 2017 7:37 am

by klweimer

I would agree with Drummond on this, but maybe I've never used roll taps? I try to use bottoming taps for thread chasing, as they have full threads almost all the way to the end, useful for blind holes.

Kirk

Re: 1980 spider Restoration phase 2

Posted: Mon Apr 03, 2017 4:07 pm

by azruss

Yes, you can use a roll tap to chase threads. The effectiveness depends a lot of the condition of the threads. If the threads have been damaged by over use (bottom A-arm studs), stripped, or cross threaded, a roll tap is a great choice. If the threads are in great shape and just need crud removed, then a cutting tap is a better choice.

FYI: A cutting tap can produce a higher percent thread depending on the size of the drill used for the hole. For instance, a 3/8x16 thread, drilled accurately with a "P" drill will produce a 64% thread. Drilled with a 5/16" drill produces a 77% thread. Roll taps normally aim for a 70% thread and is considered a stronger thread as it cold rolls the metal making it more dense than cutting. At least, that's what the experts say.

Re: 1980 spider Restoration phase 2

Posted: Mon Apr 03, 2017 11:04 pm

by DRUMMOND

Hi Azruss

Thank you! for your alternative information. Certainly something to investigate more.

Rolled taps or cut threads, Juries still out on what is stronger. Rolled taps is definitely more efficient manufacturing wise.

I had to replace the bottom A arm bolts on the cross member, as they were all cross threaded and collar worn. It seems a poor design, as the cross member does not appear to have any stabilizing tabs to stop any fore & aft movement. It appears to rely on the tightness of the bolts to prevent this. What do you think?

Re: 1980 spider Restoration phase 2

Posted: Sun Apr 16, 2017 12:13 am

by DRUMMOND