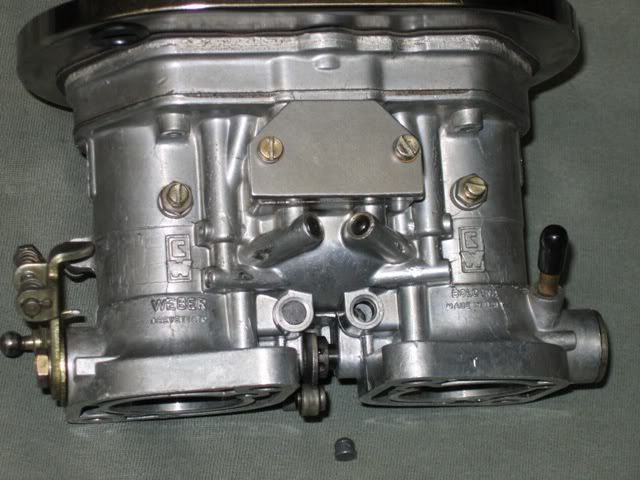

Does anyone know the proper accepted practice for putting these back in, so that they will seal off properly and stay in place? It's a lead plug with a shoulder as shown in the picture. I'm thinking that some sort of sealing Loctite might be suitable to coat the surfaces before install, then wack it home and wack it some more to make it spread out and seal, then cover the exposed end with a light layer of JB Weld. Any other suggestions?

You can imagine that it was a harrowing experience having the plug pop out while driving. It dumped about 2 gallons of fuel all over the intake manifold and engine parts below within about 2 miles of driving. I pulled into a gas station about 20 miles from home, not yet knowing the problem, but I did know that the engine was idling awfully rough, and the fuel gauge had dropped quite rapidly. I popped open the hood, saw the pool of fuel on the waffle intake manifold, and the steady stream of fuel pouring out the lower back side of the fuel bowl. I noticed that I was standing in a pool of gasoline on the pavement by now, and jumped to shut the engine off ASAP. I guess I'm really fortunate that it didn't ignite.

I had it towed home. After pulling the carburetor, I found the lead plug had lodged in a crevice between the cam tower and the intake manifold, thank goodness. I'm thinking about covering all the passage plugs with a light layer of JB Weld. A fuel leak like that could be quite a disaster!

Alvon