So what about the all important engine....?

I considered rebuilding it myself, but I had very little spare time and I'd only rebuilt one engine before, an old Ford Kent engine, and that was about about 30 years ago. I also realised the Fiat twin-cam was a a bit more 'exotic' than the rudimentary Kent engine and was something that could easily be messed up.

After lots of research the name Guy Croft kept cropping up. I wondered where Guy worked, thinking he was in the States somewhere, yet it turned out that his workshop is in Lincoln UK, about a 25 mins drive from me!! After many conversations with Guy, I decided that I should swallow my pride and get the expert to build me an engine. After all, if you think professionals are expensive, you should try amateurs!!

I told Guy that I wasn't ever planning to race my Fiat and didn't want a 'cammy' screamer but a moderately powerful and torquey car that would be civilised around town, be good on a long run. Basically, I wanted the engine to suit its sports/GT car character and not try to turn it into a hot rod. I was also worried about putting too much power through the transmission

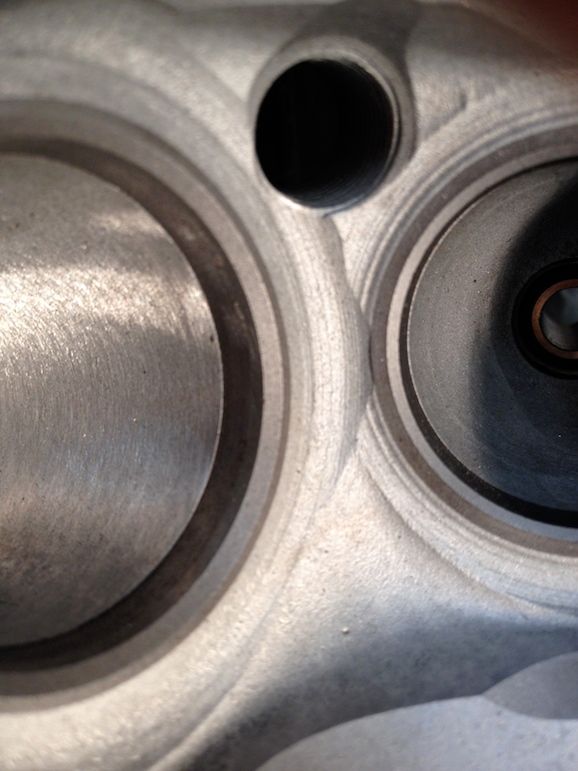

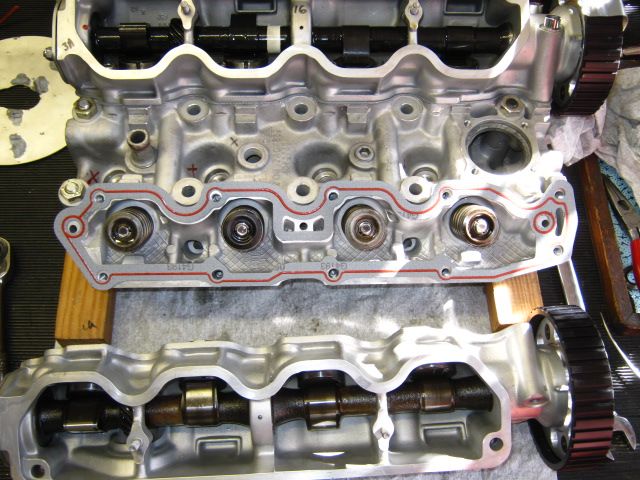

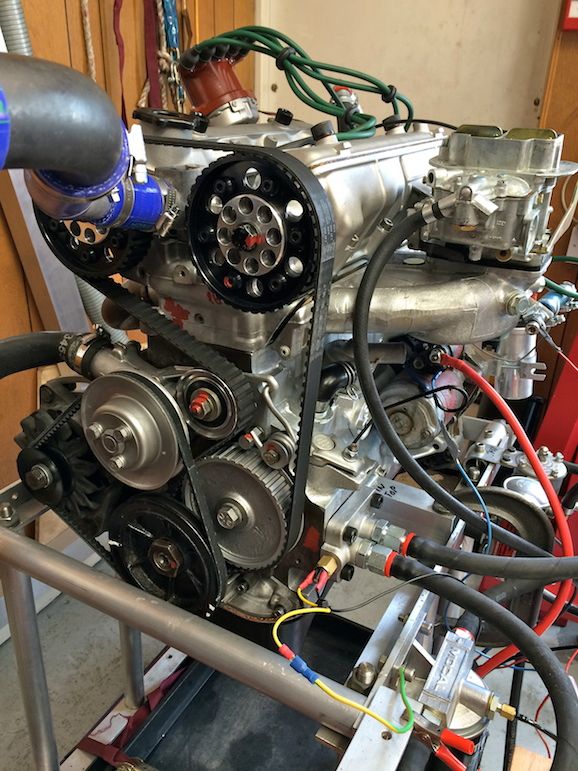

So Guy suggested using a 2.0L block as he said they were an excellent engine. He suggested a high-lift inlet cam, standard exhaust cam, HC race pistons and race rods and a single twin-choke 32/36 DGV Weber carb'. Also, the head was given the Guy croft magic with porting and flowing.

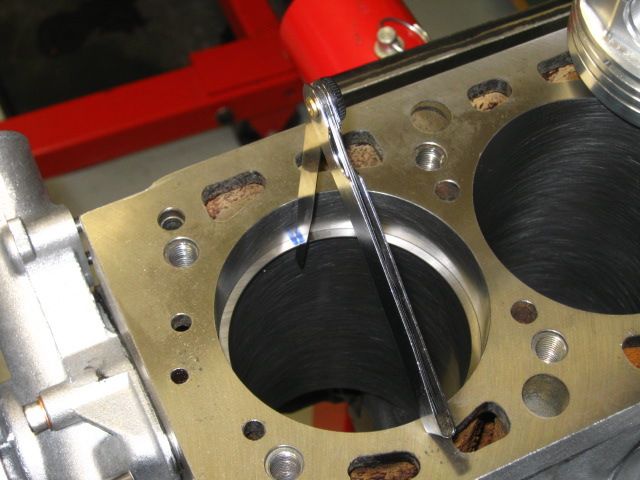

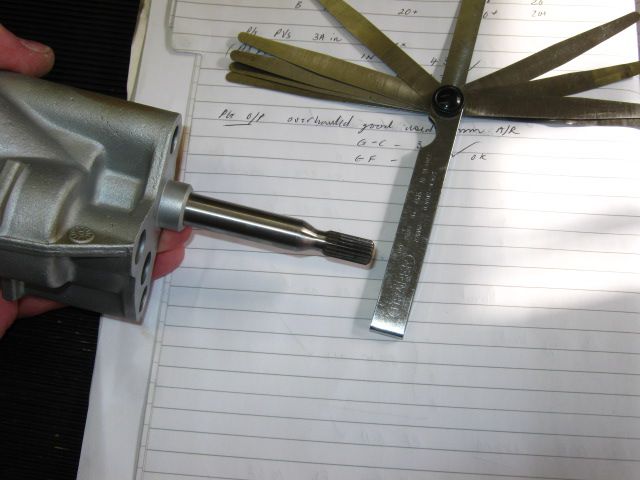

Interestingly the reason Guy insists on using race pistons and rods is for 2 main reasons; firstly despite much checking of the rods, they occasionally 'give' and Guy will not risk his reputation by using questionable yet vital components which are around 40 years old now. Secondly, using bespoke race-standard pistons that are individually made for each engine using Guy's specific design creates great efficiencies and also releases more power.

Of course I could have got bigger valves, a wilder exhaust cam and twin 40's but it is easy to get 'mission-creep' which would mean the cost would get out of hand. Also, I was looking for around 150-160 bhp and that spec' should achieve that with a decent exhaust. As I said previously, I was also concerned about putting too much power through the gearbox and differential. Doing the extra bits at a later date should easily yield around 180+ bhp but as I said, I have to get the balance of cost/reliability/economy right.

As I want to do long tours around Europe in this car, twin 40's may prove to be a pain due to poor mpg against an estimated 15 bhp power gain. Besides, if (when!) I do want more power I should be able to achieve around 170-180 bhp with just a bigger exhaust cam and porting the inlet manifold whilst still using the 32/36 Weber. I'll see how things go for now.

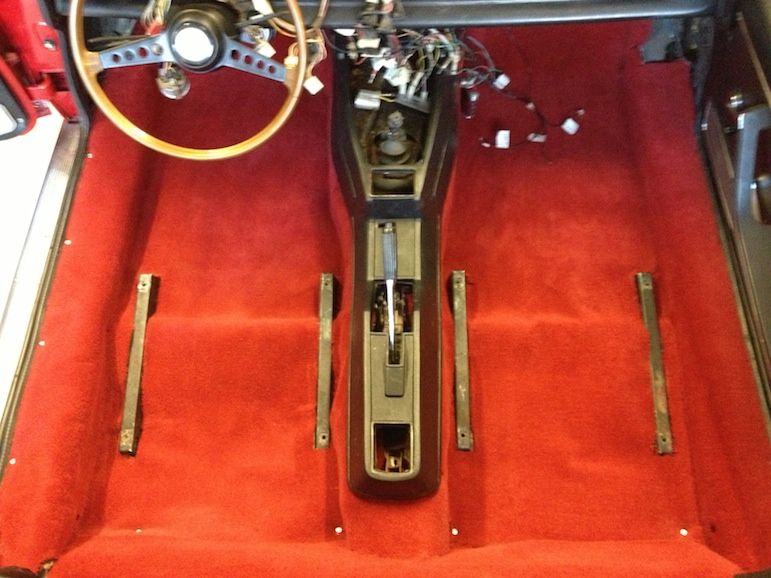

This is how I got the car

This is the finished result after its first run in the engine bay following a bench run. It will hopefully get its first road run next week.

I shall post some images showing the quality of Guy's engine building; I can tell you that it was a privilege to see his work first-hand and I realised this was money well spent and a real investment!